We Are Value-added Re-seller of Siemens PLM Solution, Solid Edge is a portfolio of affordable, easy-to-use software tools that address all aspects of the product development process. Solid Edge combines the speed and simplicity of direct modeling with the flexibility and control of parametric design – made possible with synchronous technology.

Mechanical Design

Visualize and validate your ideas with next generation technology, from augmented reality to MBD

Speed your design process ten-fold with productivity gains in areas such as large assembly, sheet metal and data migration. Integrate next-generation technologies to create digital representations of your designs, making it quicker and easier to capture a digital twin of the physical product. Validate digital designs in a physical environment using new, photorealistic design visualization capabilities, so you can truly bring ideas to life.

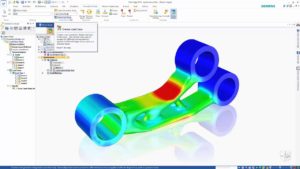

Simulation

Put your designs in motion with simulation tools built for designers, powerful enough for analysts

Digitally validate and optimize parts, assemblies and complete systems early in the design process to reduce the need for physical prototypes and save time and costs. Three new levels of simulation capabilities are now offered: Solid Edge Premium, Solid Edge Simulation, and Solid Edge Simulation Advanced.

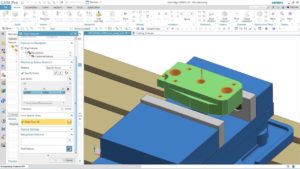

Manufacturing

Solid Edge CAM Pro provides you with the right tools to manufacture today’s products.

Solid Edge CAM Pro provides comprehensive solutions for machine tool programming, from simple NC programming to high-speed and multi-axis machining, enabling you to address all types of CNC machining requirements.

Solid Edge CAM Pro offers advanced machining capabilities such as adaptive and feature based machining, smart pencil milling, and enhanced roughing routines. Toolpaths are associative to the Solid Edge parts and assemblies so the toolpaths can be quickly updated to incorporate any design changes.

Turning

Full range of turning tool paths, including teach-mode and other manual methods for fine control.

2.5 Axis Milling

Roughing, re-roughing, facing, z-level finishing, and hole-making methods including manual positioning and feature based automation.

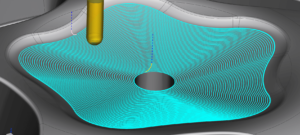

3 Axis Milling

Extensive, high-speed capable, fixed axis cutting capabilities for complex surfaces, including raster, offset, adaptive clearance tool paths, and interpolated patterns, with steep/non-steep recognition, valley rest milling, and facet machining.

5 Axis Milling

Extensive capabilities for simultaneous multi-axis cutting of complex surfaces, including both automatic and manual methods, multiple drive options and a wide variety of tool axis control.

Machine Simulation

A complete kinematic machine environment for visualizing complex motion, including g-code level simulation of collision checking and multi-channel synchronization for the most accurate results.

Feature-Based Machining

Capabilities to create and modify rules-driven automation processes and feature geometry definitions in the Machining Knowledge Editor. Feature based machining allows the built-in feature recognition engine to analyze prismatic shapes and quickly create NC strategies to machine those shapes–all automatically.

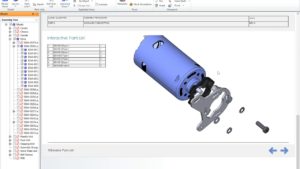

Technical Publications

Communicate your digital design documentation globally

New and enhanced publishing tools allow users to import and export Solid Edge section views, publish vector graphics for PDF documents, define individual sizing for illustrations and produce images or vectors with transparent backgrounds.

Data Management

Scalable, searchable and manageable data

From built-in data management to Teamcenter integration, Solid Edge’s scalable set of tools can meet the varying needs of all manufacturers. Search for drawings, parts and assemblies using file names and standard or custom properties for quick and easy access to data. One-step and quick-release workflows with email notifications offer simple processes for design approval. And, Solid Edge Requirements Management provides systematic and effective tracking and reporting on customer and regulatory design requirements.