ICUBE ENGINEERING SOLUTIONS Is an Authorized re-seller for ESI’s ProCAST/QuikCAST , ProCAST is a leading Finite Element solution for casting process simulation. It is an important tool in product design and process development that helps improve yield and casting quality.

ESI has developed a set of casting simulation software applications for the foundry industry to improve casting yield and quality: QuikCAST a fast and efficient solution for process evaluation and ProCAST an advanced tool which is the result of more than 25 years of collaboration with major industrial partners and academic institutions around the world. QuikCAST is sophisticated sand and die casting simulation software that focuses on the basics of any casting process: filling, casting solidification and porosity prediction.

Our Services

- Yield Improvement

- 3D Design Of Casting

- Simulation of the existing method

- New casting method design & development

- Simulation of new method design

- Standard report generation for approval

- Filling Results

- metal temperature

- metal velocity

- air movements

- air entrapment

- surface defects or oxides

- local gas pressure

- Solidification Results

- temperature

- solid fraction

- liquid fraction

- hot spots

- macro porosity

- micro porosity

- Methoding solution

Casting Simulation Suite

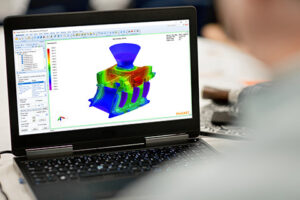

The two offerings from ESI for this sector are ProCAST and QuikCAST. Both these software are the result of extensive research and collaboration with major industrial partners and academic institutions around the world. Both ProCAST and QuikCAST improve the quality and yield of the cast.

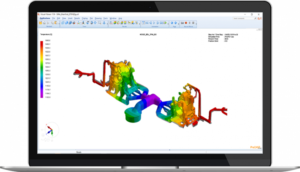

ProCAST

ProCAST is a leading Finite Element solution for casting process simulation. It is an important tool in product design and process development that helps improve yield and casting quality. ProCAST is based on powerful finite element solvers and provides an efficient and accurate solution to meet the casting industry needs. Compared to a traditional trial-and-error approach, ProCAST is the key solution to reduce manufacturing costs, shorten lead times for mould developments and improve the casting process quality. ProCAST is equally adept in predicting deformations and residual stresses. It can also address more specific processes like investment casting, semi-solid modeling, core blowing, centrifugal casting, lost foam, and the continuous casting process.

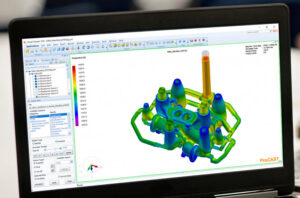

QuikCAST

The profit of foundries depends on reducing both casting time and costs. QuikCAST is a fast and efficient solution that allows users to simulate entire casting processes. The tool addresses the basics of casting process that includes filling, solidification and porosity prediction. The software also evaluates core blowing and semi-solid modelling.

While providing analysis, QuikCAST also accounts for air back pressure, filters, mold roughness, thermal exchanges, die coatings and gravity. It thus accurately simulates most casting processes ranging from gravity sand casting to high and low pressure die casting.